Acquirers of electronics manufacturers will pay more for certain types of businesses and will be more attracted to companies when they are properly described. Thus, the correct use of industry terminology can be an important part of marketing and selling your electronics business.

Background

The term OEM stands for “original equipment manufacturer”. Some years ago, OEMs designed, manufactured, distributed, and provided after-market support for all their end-products internally on a “turnkey” basis. Over time, three innovations dramatically changed the electronics industry.

- First, electronic component manufacturers exponentially increased the functionality of integrated circuits requiring the development of surface mount technology (SMT). This innovation dramatically reduced the size of electronic equipment but required a CAPEX investment in SMT equipment which was both complex and expensive. Smaller OEM’s were reluctant to invest in this new technology. That reluctance spawned the development of the contract manufacturer (CM), a manufacturing specialist initially focused on SMT serving the needs of multiple OEM’s.

- Secondly, the idea of a “virtual OEM” was born. As an example, Cisco Systems from day one decided to outsource manufacturing to CM’s. Cisco’s virtual OEM business model outperformed traditional vertically integrated telecom OEM’s in both total cost as well as the time required to get new products to market. Cisco’s virtual OEM model resulted in a manufacturing revolution within the telecom industry. Traditional telecom OEM’s sold their manufacturing infrastructure to Contract Manufacturer’s. Over time CM’s expanded service offerings that now include specialty services such as design, new product introduction (NPI), supply chain, manufacturing, logistics and after-market services.

- Thirdly, original design manufacturers (ODM’s) appeared These companies originally operating in Taiwan contracted with OEM’s to both design and manufacture select products.

Today, designing and manufacturing electronics hardware products has evolved into two segments namely OEM’s and contract electronics solutions providers.

OEM

OEMs generally fall into one of two categories. Some OEMs market complete “turnkey” end products while others market certain components or sub-systems that are re-sold by another OEM as part of their end product. OEMs typically focus on product innovation and development. Most design the majority of their products themselves and own the rights (intellectual property) to those product designs. Increasingly, electronic OEMs outsource some or all their manufacturing so perhaps the “M” in “OEM” is outdated.

Contract electronic solutions providers

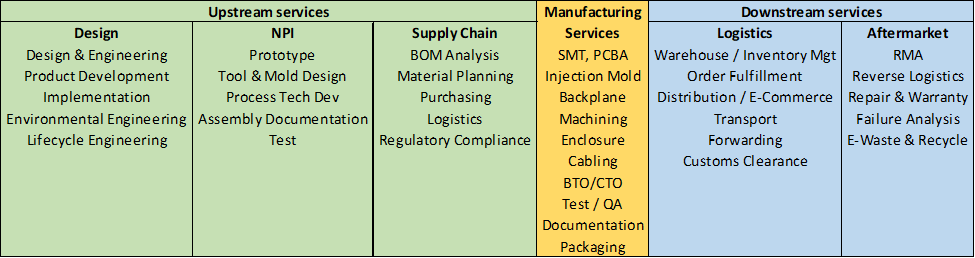

The companies in this segment contract their services to OEM customers and other solution providers to bring OEM customer products to market by offering some or all the specialized services listed below.

Upstream services (before manufacturing), as well as downstream services (after manufacturing), will result in higher profit margins for the solutions provider as compared to manufacturing only. Additionally, some providers only offer their services to OEM’s operating in select markets (medical, industrial, automotive, consumer wearables, etc.).

This segment can be further subdivided into CM, CEM, ECM, EMS, ODM, JDM, and electronic design houses.

- CM:

Contract manufacturers (CM) offer manufacturing services and often some

limited services related to manufacturing to OEM’s. The term CM is a common

term in many manufacturing sectors where production manufacturing is outsourced

including construction, electronics, food, pharmaceuticals and other consumer

packaged goods. - CEM / ECM: The terms contract electronics

manufacturers (CEM) and electronic contract manufacturer (ECM) are

interchangeable. These companies serve

the electronics industry. Note that CEM

/ ECM is always interchangeable with CM, but CM is not always interchangeable

with CEM / ECM. - EMS:

Electronic manufacturing service providers (EMS) is a term used for

companies that design, manufacture, test, distribute and provide return/repair

services for OEM’s. The EMS industry is commonly divided into tiers based on

revenue:- Tier 1:

> $5B - Tier 2:

$500M to $5B - Tier 3:

$100M to $500M - Tier 4:

< $100M

- Tier 1:

Another distinction is drawn between EMS that specializes in High Mix Low Volume (HMLV) and High Volume Low Mix (HVLM). Mix refers generally to the complexity or different models of the PCB assembly. Volume refers to the number of units built, with products like consumer electronics on the high end and prototype, medical electronics or machinery on the low end. Typically, lower-tier EMS provide HMLV and higher tier provide HVLM.

- ODM: An original design manufacturer (ODM) is a company that designs and manufactures products that are eventually rebranded by another firm for sale. ODM manufacturing can be subdivided into white label and private label. ODM white label is where the ODM designs, manufactures, distributes non-label, generic FGI products to various outlets or retailers. These retailers then sell the ODM product under their own logo or brand name. ODM private label is where the end product is produced exclusively for a particular retailer or OEM.

- JDM: A joint design manufacturer (JDM) refers to companies that work with OEM’s to jointly design products and then manufacture those products. The JDM model is about collaboration from start to finish. A hardware OEM generally kicks off the collaboration with a detailed specification for a product that can’t be built with off the shelf parts. The JDM will then set about designing the product, with careful input and oversight from the outsourcer. The two teams will work together to navigate tradeoffs, obstacles, design revisions, testing, factory flow, and more, until you have a shippable product. Typically, both companies will share ownership (IP). Sometimes the JDM is compensated in the form of earnouts where payment includes both design contribution and product volumes shipped.

- Electronic design house: Electronic design houses provide software and electronic hardware product development services for government agencies and private industry. Services may include Project Definition & Scope, Electronics Hardware Development, Firmware/FPGA Design, Rapid Prototyping & Small-Volume Manufacturing, Custom Software Development, Testing & Support.

Summary

The roles of various organizations within the electronics industry are often confused. This situation is in part due to both the evolving role of companies within this space as well as the significant amount of overlap of activities among companies operating in this segment. As a result, there is frequent misuse of terms.

If you are considering acquiring or divesting of an electronic OEM or contract solutions provider, we recommend that you partner with an M&A Advisor who has considerable demonstrated experience in the electronics segment. If you are an OEM it is important your advisor outlines your entire product development and manufacturing business model. This requires a knowledgeable M&A Advisor. Buyers will pay more for OEM’s that operate a high-performance outsourced business model. If you are a contract solutions provider your advisor needs to outline and describe the various services offered by your company and the resulting financial impact those services deliver to the organization. An advisor with direct experience within the electronics segment will connect you with the correct competent buyers and ensure maximum valuation for the business.

Charlie Fay has over 30 years of experience in the electronics industry including engineering, leadership roles, and work on over 100 acquisitions. Learn more about Charlie here.